| USTC Products |

|

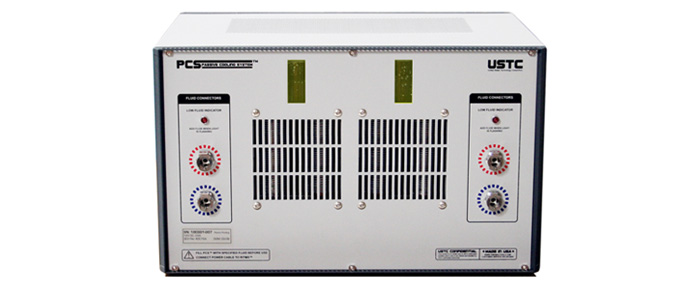

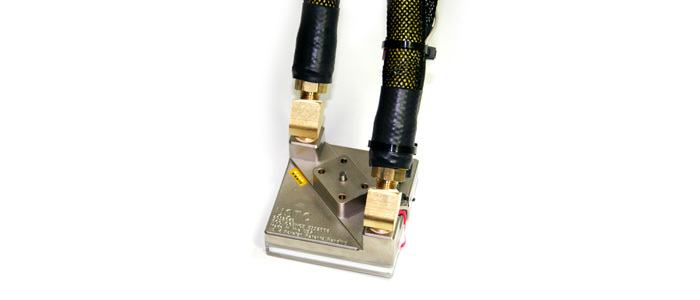

USTC specializes in Thermal Management on a Processor and delivers solutions that integrate direct Thermal Head™ contact on a CPU with the variety of controllers, air and liquid cooling systems used for a broad range of processor control options. In 1996, USTC made the first Thermal Solution for managing the heat on an Intel® Slot1 CPU. To optimize thermal testing in a bench-top environment, USTC developed an optimal turnkey solution that integrated all the necessary components to design, debug and validate processors and chipsets. USTC has designed and delivered a wide selection of solutions called Thermal Tools™ for micro-processors since 1995. Many usage models exist in areas of systematic testing at high and low temperatures, of validation by cycling the temperature and of debugging by margining the temperature of different components. All USTC hardware is Made in the USA. USTC Thermal Tools™ facilitate temperature control of a device under test (DUT) in the system environment. A standard system environment includes a DUT in a test platform with a Thermal Head (TH) attached to the surface for automated or manual control, for cycle tests at different temperature levels and for focused control to test at specific temperatures using the USTC Rack Integrated Thermal Management System (RITMS) or other control means.

Thermal Head™ options Temperature range options

Controller options Solutions in the Microprocessor Environment The chip industry continues making ICs with ever more transistors, with exponential increases in the amount of power they consume, and thus the amount of heat generated. This has not yet slowed the rate at which processing speeds increase, but thermal concerns have taken on a critical dimension. Advanced thermal solutions in the qualification phase are needed to validate the processor performance so that systems can work around this “power wall.” USTC has solutions that excel in a wide variety of applications with a wide range of standard solutions. USTC offers customization in applications for meeting even more stringent testing requirements. USTC Thermal Tools™ facilitate temperature control of a device under test (DUT) in the system environment. A standard system environment includes a DUT in a test platform with a Thermal Head (TH) attached to the surface for automated or manual control, for cycle tests at different temperature levels and for focused control to test at specific temperatures using the USTC Rack Integrated Thermal Management System (RITMS) or other control means. Many USTC usage models exist in areas of systematic testing at high and low temperatures, of validation by cycling the temperature and of debugging by margining the temperature of different components. USTC Goals To provide thermal management solutions in conjunction with developers during the early stages of board design and component selection. To participate in equipment and system designs for cooling and thermo stabilization to improve component performance and reliability. To deliver a product that supports a strategic advantage through reliable test and validation methods, on-time delivery, value-added features and plug-and-play set-up and operation. Application Suggestions

The greater complexity and power dissipation density of integrated circuits and systems has made testing exponentially complex and time-consuming. As developers speed up the design validation of processors and other electronic components, they subject the device to conditions the product may never see in normal operation. This can create extreme temperatures at which the device may actually be destroyed due to package failure or extreme localized hot spots, and eliminates the ability to study the functional failure in a repeatable manner. Controlling the temperature applied to a processor or electronic component facilitates the debugging by repeatable access to failure conditions, thus allowing design evaluation and debugging of the same or additional components over and over. USTC uses a TH with proprietary heat-sink designs (OR heat dissipation mechanisms), patented flow techniques, to align with user needs for thermal patterns required for testing. These patented and proprietary techniques and heat-sink designs allow USTC to provide solutions that balance the user’s immediate requirements and system design roadmaps. Characterization In order to optimize the design for desired performance and the best yield of electronic components, prototypes can be stressed to the extremes of temperature and operating voltage. Optimal margins and characterization data also guide thermal test conditions to sort devices for specific applications, allowing manufacturers to make informed pricing decisions depending on the component characteristics. Whatever your requirements, the USTC team is your one-stop, full service, choice for thermal management solutions. |